In 1978, I bought a wind-up donkey for my daughter, then an infant. The

donkey moved its head while playing “Donkey Serenade.” I figured that I could replicate that with an

Arduino, a motor, sound on an SD card, and a speaker. It took me 10 weeks, but I did it. Here’s the

story.

I got sidetracked for a while doing

my

Halloween Candy Cauldron, which came out of this one. While I was working

on the donkey, learning about playing sound with an Arduino, I began seeing

lots of Halloween projects on Adafruit shows, so I decided to try my hand on

Halloween sounds.

This was an incredibly rewarding project that was challenging, fun,

interesting, and educational—all the reasons I wanted to start with Arduino in

the first place!

Parts List (about $80 in parts

done this way, assuming you have all the tools and supplies)

Micro SD Card

Speaker (I used a 2” 8ohm speaker from an MFC printer I took apart)

Hook-up wire (I used 22 gauge solid wire to connect the speaker, and to

run from the terminal block on the PWM board to the power connector because

that was easier

Header pins (male, female, and right-angle)

Soldering iron and accessories

Heat Shrink tubing

Dremel or similar tool for cutting out the stand-offs on the enclosure

Drill and bits for making holes in the enclosure (1 for the power jack

and 1 for the wires to the speaker and servo)

Electrician’s tape to keep stuffing out of the wire hole

Needle and thread

Step 1: play music

Step 2:

operate servo

Step 3: put it together

Step 4: getting small

I asked Becky Stern, Director of Wearable Technology

at Adafruit, for some advice on getting all this in a donkey. She

answered my question on Wearable Wednesday (~21:30)! I also needed to change some components.

First I swapped out the Arduino Uno for a Pro Mini 5V (I thought). Next I bought a microSD breakout to replace

the shield. The Micro SD runs on 3.3V, so I thought I needed a voltage

regulator and maybe something else (http://forums.adafruit.com/viewtopic.php?f=19&t=60813 ). In the process

I found out that the 5V pro mini was really a 3.3V, and figured out that that

was really what I wanted (power the Pro Mini, the amplifier, the PWM board, and

the servo from the battery, and power the SD from the Mini).

Step 5: refine

I figured out how to play the song in a loop without

resetting the Arduino (TMRpcm.loop(1)). In the process of doing all this I

cooked my Mini—it won’t put out 3.3V anymore (more like .9V) so I’m back on the

Uno until my 3V Pro Trinket comes next week.

I also decided to go with a 6V coin cell holder with switch (https://www.adafruit.com/product/783 ) for power. I

gave up on the amplifier and put in an LM386 circuit. It works OK, but I also ordered an amplifier

breakout (https://www.adafruit.com/product/2130) just in case I can’t get the sound I want out of a smaller

speaker.

Step 6: construction

Donkey arrived 10/4/2014. It will accommodate a small project box,

servo, speaker, and battery holder. Now I need to be sure I can get the whole

circuit on a board small enough to fit into the enclosure. The Altoids tin will

fit in the donkey, but I also have a project box if I can’t get the circuit in

the Altoids tin.

Programming the Pro Trinket was somewhat flaky at

first. I needed to install the hardware updates for the Arduino IDE so it would

recognize the board. Also, had to set the programmer to USBTinyUSB. When that

didn’t work (“can’t find USBTiny”) I discovered I needed the Windows

drivers. After I got that all done I was

able to upload the example blink program, so I’m in business, I think. Now I

need to solder the headers so I can test the circuit. I have another Pro

Trinket coming tomorrow, so I will use that for the real thing, soldering

directly, but I’ll need this one with the headers anyway. UPDATE: there may be an issue with the ProTrinket and

device recognition on Windows (or at least my Windows systems). I got it to work with Ubuntu, and in the

process discovered that the upload took longer than the bootloader was active,

so I have to wait to press the reset button to activate the bootloader, but

leave enough time in the compile process for it to initialize. Kind of a pain, but it’s working. I never did

get it working on Windows 7 (that may be my fault), but it’s working OK on

Windows 8 and Ubuntu.

Step 7: more construction

I tested the 6V coin cell battery, and the power

lights on the boards come on but no music and no motion. I need find another power source. I’m

considering a 9V with a voltage regulator to bring it to 5V. A 4bXAA works (6V)

but it’s big. Also I got the Adafruit mono amp, and it puts out more volume

than the LM386. I also takes up a lot less space. Next, I got some SMT breakout

boards (https://www.adafruit.com/product/1208) so I’ll see if I can solder the TSSOP-28 PCA9685 to it

and save more space. That didn’t work—not skilled enough. I will try to make a

DIY breakout. I shorted something and cooked my amp, just got new amps today

and will try again. The servo moves but no music…hopefully the new amp will get

me back where I was. The new amp fixed the problem. I decided to stick with the

Adafruit PCA9685 PWM board because my surface mount skills are not there yet.

Step 9: The enclosure

I got a 4x2x1

enclosure from Radio Shack.

I fixed an Adafruit 1/8 size Perma-Proto Board to the enclosure with a

screw, and drilled a ½” hole for a power receptacle and a 3/8” hole for the

servo and speaker wires. In another 3V Pro Trinket, I soldered female headers

to A4&A5 and Adafruit silicone coated flexible wires to the pins I need for

the circuit. I put right angle headers on the I2C pins of the PWM board, so I

can slide those into the female headers and have the bigger board flat with the

Trinket on its side perpendicular to the PWM board. All the power and ground

connections will go to the Perma-Proto Board + and - rails, with the power

connector supplying those rails. The

power supply will be an Adafruit 4xAA battery pack with switch so there is an

external switch access to batteries for

changing without opening the donkey, and less space to take up inside.

Step 10: new Trinket

I tried wiring up the circuit with the new, newly soldered

Trinket. It powers up, and puts out 3.3V on that

Rail, but it does not play sound or move the motor.

Either I did not wire it correctly or there is something wrong with my

soldering. More testing tomorrow.

The next week:

I wired it up again. After some

fussing with connections I got the whole thing to work. I spent some design

time on the enclosure, so on to soldering/enclosing.

Step 11: The enclosure, part 2

Day 1: I

discovered that I could not fit the Perma-Proto board and the other components

in the enclosure. The next size larger

is too big for the donkey. Also, the

internal stand-offs in the enclosure were in the way, so it was redesign

time. I moved the power

connector/receptacle from the end to the side to give more room. I used my

Dremel knock-off tool to cut out the internal standoffs. Now everything

fits. Without the Perma-Proto Board, I

will need to connect the wires for power and ground directly to the connector. Next

I got to soldering:

1.

I connected a

2.1mm jack (to plug into the power receptacle) to the battery pack and covered

the splices with heat shrink tubing.

2.

I soldered

new, solid core wire leads to the speaker.

Solid core works better in the terminal blocks.

3.

I connected

solid core wire to the external power terminal block on the PWM board, and ran them

under the board to the power connections.

4.

I removed the

jumper wires from the amplifier, and soldered wires directly to the header

pins. The A- and GND wires to go to GND,

the Vin to go to power, and the A+ pin is soldered to the wire going to digital

pin 9 on the Trinket (SpeakerPin).

So far, so good. Tomorrow I’ll replace the six jumper

wires on the SD card with direct soldered connections, and test the audio.

Assuming that works, I’ll do the 4 remaining wires on the PWM board.

Step 11: The enclosure, part 3

It works!

Without the circuit board there was a lot of soldering. I soldered all

the power leads together, two at a time, adding the next one in turn until I

had one lead to connect to the power connector + lead, then did the same with

the grounds, to the – lead. I left the

jumper wires on the SD board because they’re pretty secure and didn’t want to

risk cross-connections due to sloppy soldering.

I did solder leads to the headers for Vcc and GND on the PWM board. For the SD board, I cut and stripped the

jumpers and connected them to the correct leads:

·

GND to the

GND complex

·

3.3V to the

3.3V pin on the Trinket

·

SPI pins to

the leads I already had soldered to Trinket pins 10-13

I used heat shrink tubing on the splices to protect

the connections from touching.

Everything fits—I can close up the enclosure and

secure it with screws. The music plays and the servo moves.

Tomorrow: open up the donkey.

Step 12: the donkey 1

I used an x-acto knife to cut the donkey’s belly

along a seam, and took out some stuffing.

I got the servo in the neck, and it will turn the head, but I need to

fix it to something solid so the horn of the servo turns the donkey instead of

the donkey holding the horn while the servo turns. Meanwhile, I stripped the

plastic gears on the servo. This is the

second servo I’ve ruined. So, I ordered

two new servos, one micro and one standard, both with metal gears from

Adafruit. Hopefully one of them will do the trick.

Step 13: the donkey 2

I used the standard servo. It’s substantial, and it

does the trick. I was able to close up the enclosure and screw on the cover

with only one mishap: the ground lead on to the power connector broke and I had

to de-solder/re-solder it. I pulled more

stuffing out of the head to get the servo in closer. It moves a little, but

with more stuffing, it should be even better than it is now. There’s a little interference from the servo

(actually I think it’s from the PWM board) but it’s OK.

Next: sew on the Velcro and re-stuff.

Step 14: the donkey 3

First, I sewed on strips of Velcro that I had cut to

the length of the slit in the donkey’s belly.

I’m not great at sewing, so it was a little frustrating, but I got

through it. Next, I tried different

positions for the servo to get it to move the head. I re-stuffed the neck to

try to keep the servo in position, placed the speaker, re-stuffed the rest of

the donkey put the enclosure in and closed the Velcro. After one more iteration to get the servo

better positioned, it’s done. I’d like

more range of motion on the head, but it does move.

Step 15: futures

1.

I’d like to

get more movement from the Servo. I have to experiment with different horns,

different positions, and different programming.

I was time-limited on this one—I needed to have it ready for

Thanksgiving Dinner, so I haven’t been able to pursue more options yet.

2.

I would

shorten the wires inside the enclosure, and probably move the power connector

to the end of the box (rather than coming up from the bottom).

3.

I’d also like

to find a box that fits the components a little better, and to fasten the

boards to the enclosure (right now, they’re loose, and any jostling by

grandchildren may disconnect something). I think I could put standoffs on the

end of the enclosure for the Trinket and the bottom for the PWM Board.

4.

Rather than

connect the Pro Trinket to the PWM board via right-angle headers, I might want

to solder wires directly from the holes on the Trinket to the holes on the PWM

board.

5.

To accomplish

#3 and other improvements, I would need to hold off on soldering header pins to

any components until I know how I really want to wire up and solder the whole

project. I soldered the headers first thinking generically, then when I got

inside I found that some of the pins were in the way.

6.

I’d like to

see if I can make a PCA9685 breakout on my own to save space. New Year’s

Resloution #1: get some SMT soldering

skills.

7.

Investigate

60MHz vs 50MHz on the Servo (see comment in sketch)

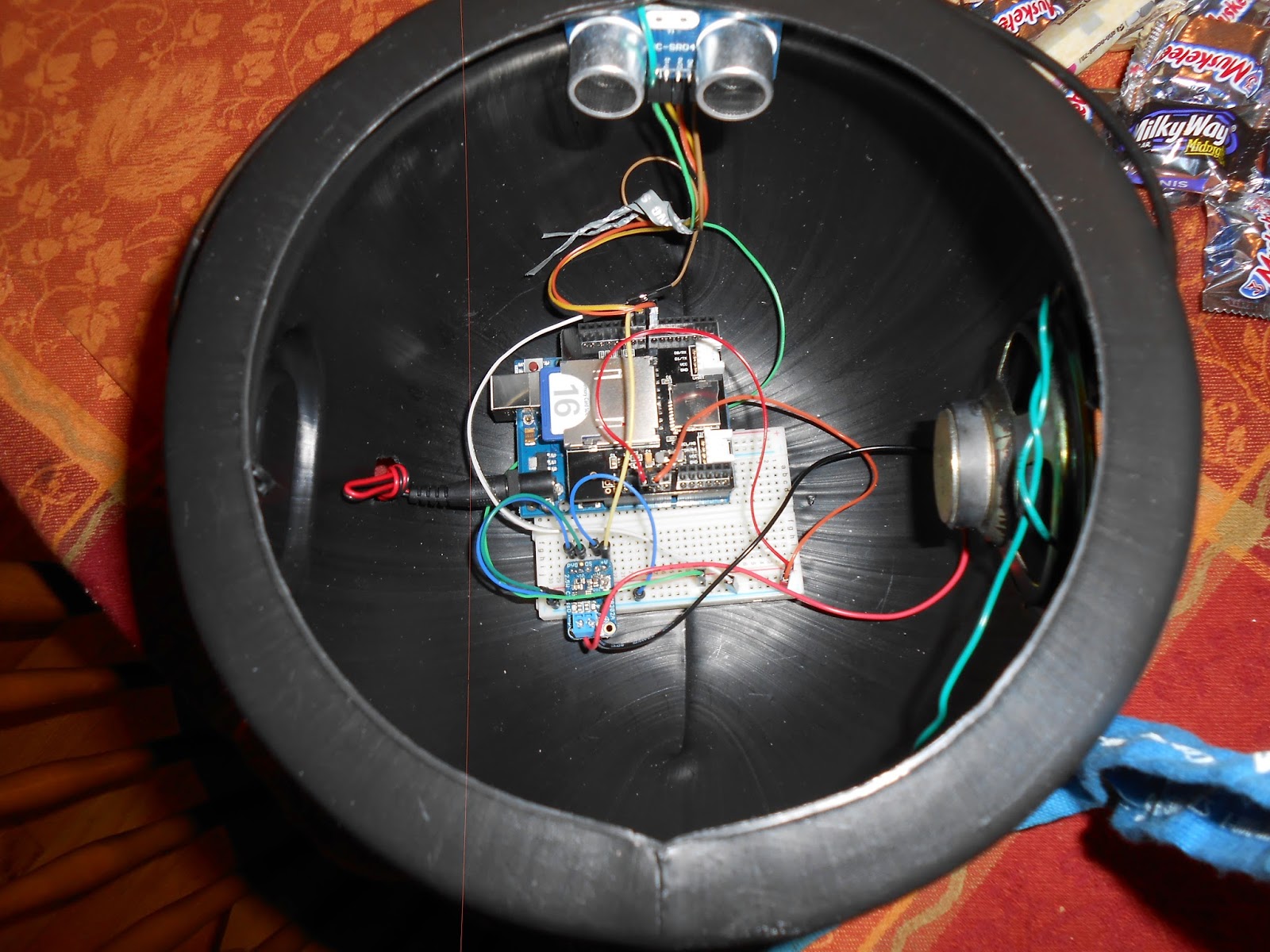

Circuit as laid out on a

breadboard

Resources

Presentation

on Adafruit Show-and-Tell

In-Process https://www.youtube.com/watch?v=Y8tFcF2-klw about minute 13 to 16:30

Finished http://www.adafruit.com/blog/2014/11/26/show-and-tell-google-live-hangout-wednesday-night-at-730pm-et-112614-video/ about 4:50 to 6:45

Discussion on Wearable Wednesday

http://www.adafruit.com/blog/2014/09/17/wearable-electronics-with-becky-stern-9172014-live-2pm-et/

Donkey:

Sound:

Tutorial:

Sound from SD:

Micro SD:

TMRpcm library

Power servo

PWM/Servo Breakout

Amplifier

Increase volume (LM386)

Amplifier I used

Servo I finally used

Arduino Sketch

/*September-November

2014

THE HEAD MOVE DONKEY

Uses TMRpcm library to

play music from and SD card, and Adafruit_PWMServoDriver library to drive the

servo.

Some comments are from

example code that came with those libraries

Objective is to move the

donkey's head with the servo while playing "Donkey Serenade.

When I was on the Uno

and had the serial monitor, I used an led to prove that I was moving through

the loop. That is now commented.

Circuit uses the

Adafruit Class D mono amp, Adafruit PWM servo board driving a micro servo, a

micro SD card board, an 8 ohm speaker, and a 4xAA batter holder

It now runs on an

Adafruit 3V Pro Trinket, feeding 3V to the SD card and using battery power for

the Trinket, Servo, PWM board, and amp

*/

/*includes*/

#include <Wire.h>

#include

<Adafruit_PWMServoDriver.h>

// called this way, it

uses the default address 0x40

Adafruit_PWMServoDriver

pwm = Adafruit_PWMServoDriver();

// you can also call it

with a different address you want

//Adafruit_PWMServoDriver

pwm = Adafruit_PWMServoDriver(0x41);

#include <SD.h> //

need to include the SD library

#include

<TMRpcm.h> // also need to include this library...

/*constants*/

// Depending on your

servo make, the pulse width min and max may vary, you

// want these to be as

small/large as possible without hitting the hard stop

// for max range. You'll

have to tweak them as necessary to match the servos you

// have!

#define SERVOMIN 200 // this is the 'minimum' pulse length

count (out of 4096)

#define SERVOMAX 350 // this is the 'maximum' pulse length

count (out of 4096)

/*SERVOMAX reduced from

600 in example to 500 to save the servo (I stripped the gears on one

already). That gave me ~160

degrees.

I reduced it again to

350, so it goes ~90 degrees: 45 to left and 45 to right if I have the motor and

horn positioned properly. That's what I want

*/

// our servo # counter

#define SD_ChipSelectPin

10 //using digital pin 4 on arduino nano

328 2014-09-03 changed to 10 to match datalogger

//#define ledPin 5 //pin to control led 2014-10-25 testing

/*variables*/

int angle = 0; // servo position in degrees

uint8_t servonum = 0;

/*objects*/

TMRpcm speaker; // create an object for use in this sketch

void setup(){

speaker.speakerPin = 9; //11 on Mega, 9 on

Uno, Nano, etc

speaker.loop(1); //2014-10-03 play repeatedly

Serial.begin(9600);

if (!SD.begin(SD_ChipSelectPin))

{

// see if the card is present and can be initialized:

Serial.println("SD not

initialized");

return;

// don't do anything more if not

}

else

{

Serial.println("SD

initialized");

}

speaker.volume(1);

speaker.play("hmd.wav"); //play

Donkey Serenade each time the arduino powers up, or is reset (as of 2014-10-03,

plays repeatedly)

pwm.begin();

pwm.setPWMFreq(50); // Analog servos run at ~60 Hz updates (says

Adafruit--I found that 50 worked better with my servo from Radio Shack—never

set it back for the Adafruit servo)

}

void loop()

{

//blink led to show

arduino is looping through this whether servo moves or not

// digitalWrite(ledPin, LOW); // 2014-10-25

testing only

delay(1000);

// digitalWrite(ledPin, HIGH); //testing

for (uint16_t pulselen = SERVOMIN; pulselen

< SERVOMAX; pulselen++) {

pwm.setPWM(servonum, 0, pulselen);

delay (100); //was 50, doubling the delay

to move the head more slowly

}

delay(1000); //pause when limit is reached

for (uint16_t pulselen = SERVOMAX; pulselen

> SERVOMIN; pulselen--) {

pwm.setPWM(servonum, 0, pulselen);

delay (100);

}

delay(1000); //pause when limit is reached

}

.jpg)

.JPG)

.JPG)